ELS-P1

External Lubrication System

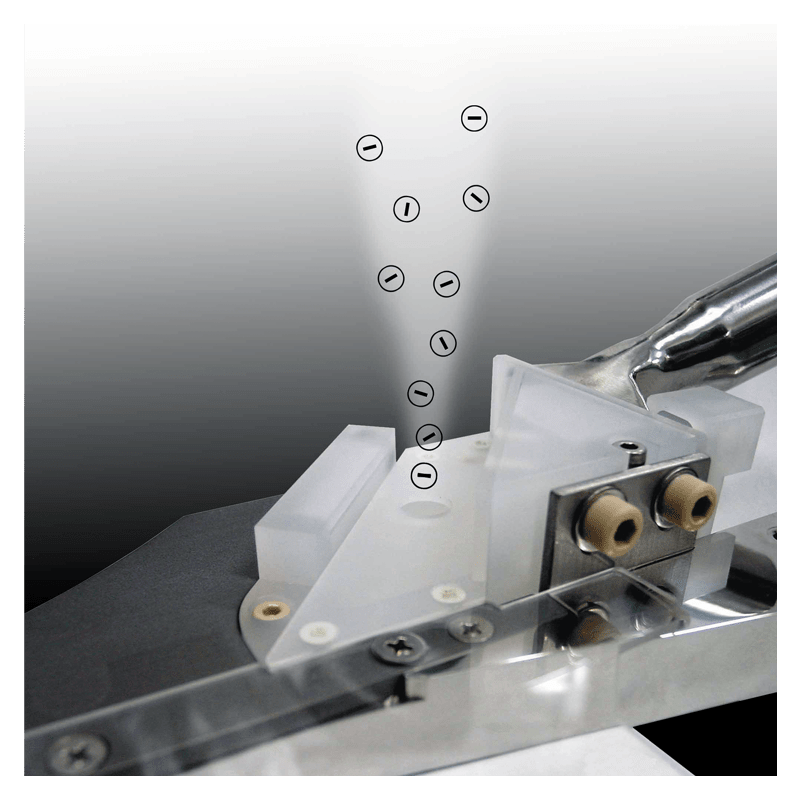

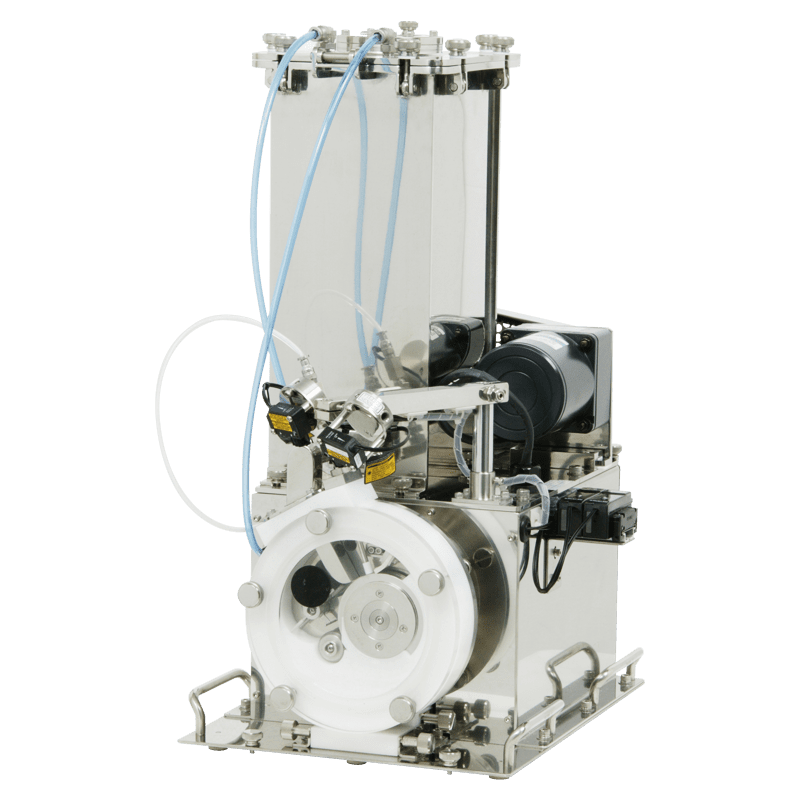

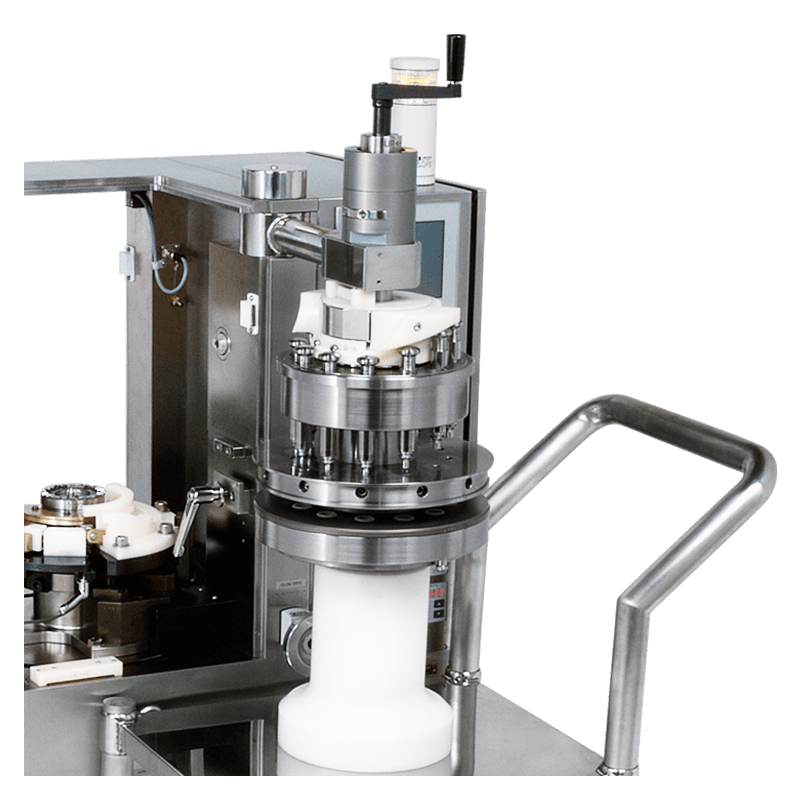

ELS is a system designed to spray a measured amount of lubricant onto punch tips and die bores to create a lubricant film on those surfaces, complete with dosing and spraying system including nozzles and vacuum collections.

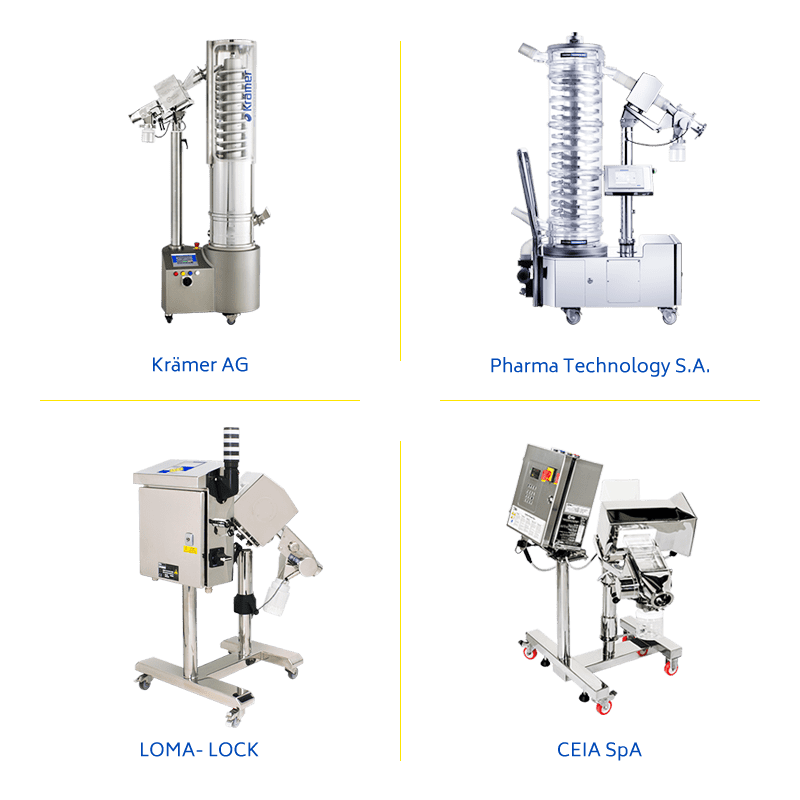

ELS helps to prevent tablet sticking on punches and to reduce die friction, and allows reduction of lubricant inside the formulation, preventing problems that are usually associated with the use of internal lubricants (soft tablets, poor dissolution profile). Different version and solution are available depending on the level of control required for distributed powder.

Product Features

The rotor speed is 2.0-6.0 rpm spraying a throughput capacity 2g ~ 90grams/hour.(See the basic specification sheet). The machine dimensions are approx.W800mm×D575mm×H1,356mm.

The external finish is stainless steel. The powder contact parts are manufactured of Stainless Steel 304 with mechanical polishing.

-

Feeding type Narrow groove feeding Spray Type Air flow Rotor speed(rpm) 1.0~20.0 Feeding capacity 10~100

Roll size 1.3mm×1.3mmRoll size 1.3mm×1.3mm

Minimum spray air(NL/min) 12 Minimum air compression(Mpa) 0.5 Spray Type Continuous spray split type Number of spray nozzle One each for Upper and Lower punch Static electricity generator Digital indication Feeding type Narrow groove feeding Spray Type Air flow Rotor speed(rpm) 1.0~20.0 Feeding capacity 10~100

Roll size 1.3mm×1.3mmRoll size 1.3mm×1.3mm

Minimum spray air(NL/min) 12 Minimum air compression(Mpa) 0.5 Spray Type Continuous spray split type Number of spray nozzle One each for Upper and Lower punch Static electricity generator Digital indication