-

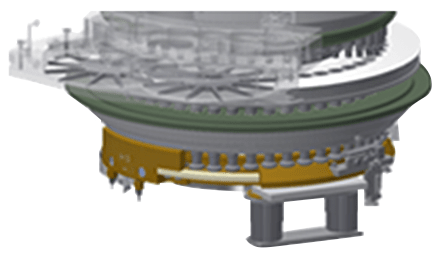

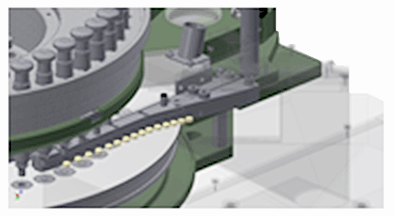

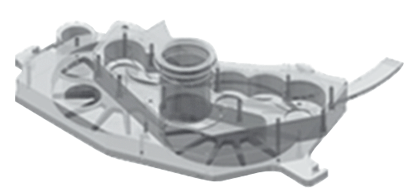

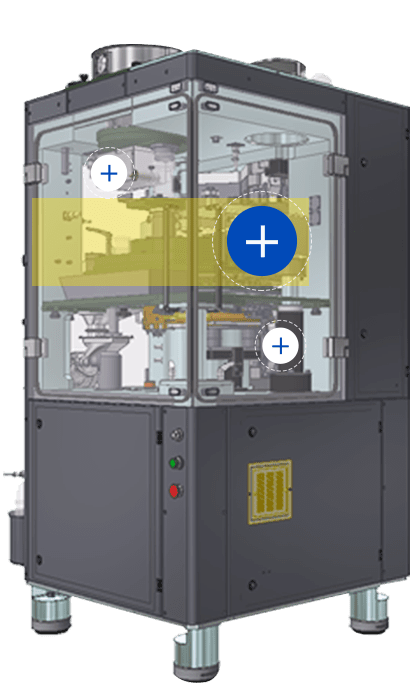

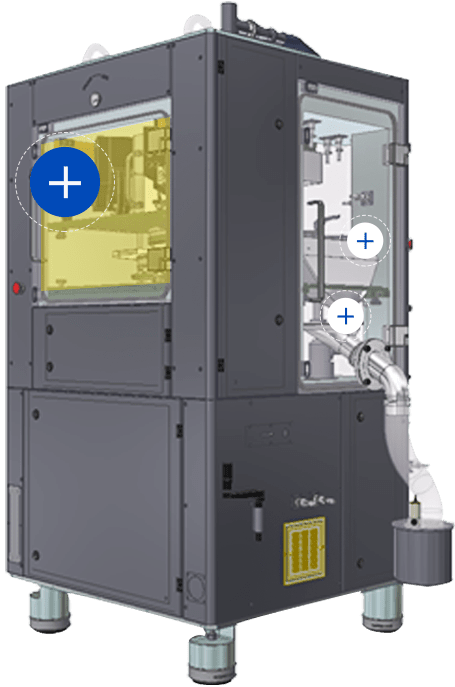

INDUCED DIE FEEDER (IDF)

When handling difficult blends/granules, the problem of uneven feeding can occur in the tableting process. In order to prevent the production of tablets with weight variation, we introduced our Induced Die Feeder. IDF allows easy and consistent feeding of all types of blends/granules into the die cavity.

2 feeding options are available, Closed feeder or Recirculation feeder, depending upon blend characteristics.

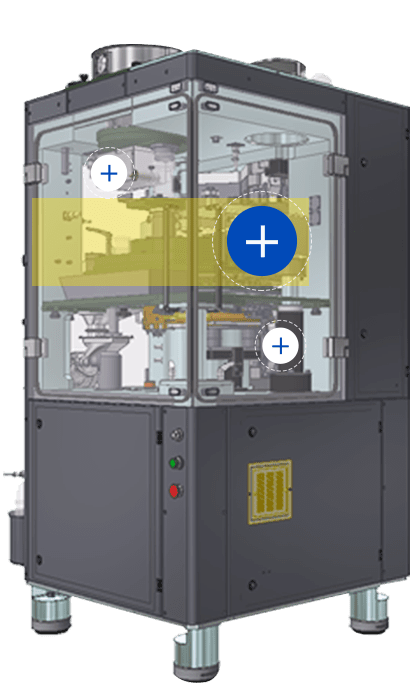

INDUCED DIE FEEDER (IDF)

When handling difficult blends/granules, the problem of uneven feeding can occur in the tableting process. In order to prevent the production of tablets with weight variation, we introduced our Induced Die Feeder. IDF allows easy and consistent feeding of all types of blends/granules into the die cavity.

2 feeding options are available, Closed feeder or Recirculation feeder, depending upon blend characteristics.

-

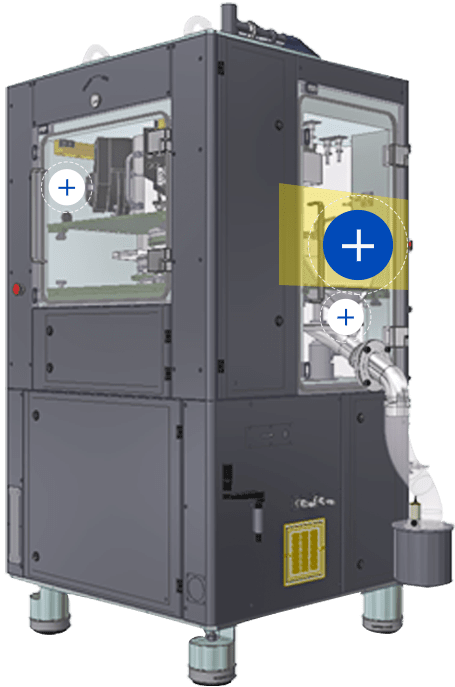

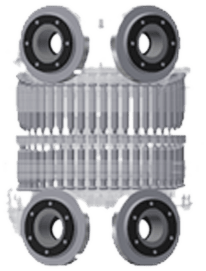

Compression

Compression molding process is done by Upper and Lower punches going through Upper and Lower rollers. The process consists of 2 steps, large Preliminary and Main compression molding. In addition, Compression force reading system is equipped on compression process to monitor the actual pressure generated with real time. Compression force data is transferred to the control system to give feedback to volume rail to be constant compression force and to reject defective tablets at tablet discharge portion.

Compression

Compression molding process is done by Upper and Lower punches going through Upper and Lower rollers. The process consists of 2 steps, large Preliminary and Main compression molding. In addition, Compression force reading system is equipped on compression process to monitor the actual pressure generated with real time. Compression force data is transferred to the control system to give feedback to volume rail to be constant compression force and to reject defective tablets at tablet discharge portion.

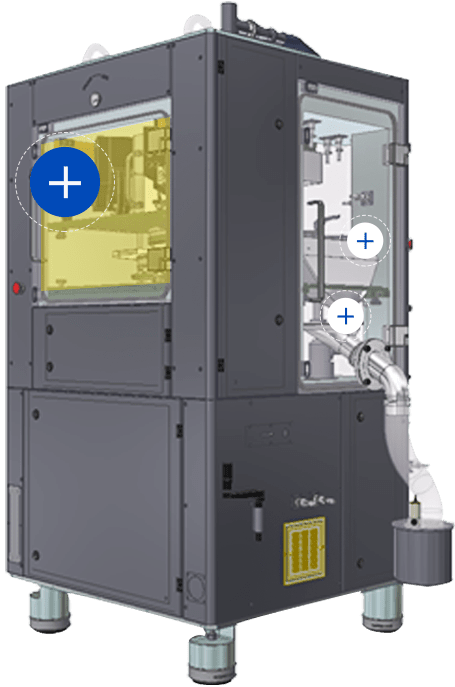

Main Shaft Drive

The main shaft drive rotates the die tablet located on the main shaft. The system is designed whereby the die table is driven by a large, precision ground worm gear located in the base of the machine, in a sealed oil bath. As a result, backlash is eliminated and fewer parts are used, greatly reducing the possibility of drive failure.

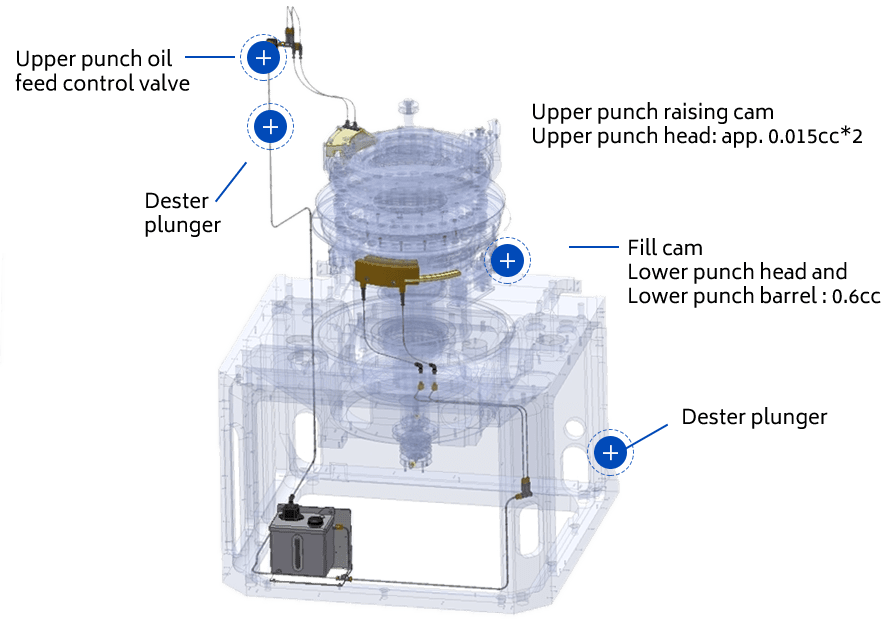

Lubrication

The machine has an automatic lubrication system to feed lubricant to upper/lower cam tracks and punches. The oil pump operates automatically with the adjustable feeding time as well as manual operation.